Earthquake-resistant structures using repairable connections with increased lifetime and sustainability

Dr. Kanyilmaz coordinated the research project DISSIPABLE “Fully Dissipative and Easily Repairable Devices for Resilient Buildings with Composite Steel-Concrete Structures”, funded by EU-RFCS with contract n. RFCS-PDP 800699, 2018-2021. DISSIPABLE team performed large scale demonstration of the steel-concrete composite structures with anti-seismic reparable systems. In the project, systematic post-earthquake repair and reassembly procedures have been developed which have been provided as “instructions for use” in the end. The life cycle economic and environmental benefits of the tested systems have been also quantified.

More details can be read in the following articles:

Alper Kanyilmaz, Milot Muhaxheri, Carlo Andrea Castiglioni, Influence of repairable bolted dissipative beam splices (structural fuses) on reducing the seismic vulnerability of steel-concrete composite frames, Soil Dynamics and Earthquake Engineering, Volume 119, 2019, Pages 281-298, ISSN 0267-7261, https://doi.org/10.1016/j.soildyn.2019.01.007

Carlo A. Castiglioni, Alper Kanyilmaz, Luis Calado, Experimental analysis of seismic resistant composite steel frames with dissipative devices, Journal of Constructional Steel Research, Volume 76, 2012, Pages 1-12, ISSN 0143-974X, https://doi.org/10.1016/j.jcsr.2012.03.027.

M. Valente, C.A. Castiglioni, Alper Kanyilmaz, Dissipative devices for earthquake resistant composite steel structures: bolted versus welded solution, Bull Earthq Eng, 14 (12) (2016), pp. 3613-3639, doi: https://doi.org/10.1007/s10518-016-0002-9

M. Valente, C.A. Castiglioni, Alper Kanyilmaz, Numerical investigations of repairable dissipative bolted fuses for earthquake resistant composite steel frames, Eng Struct, 131 (2017), pp. 275-292, DOI: https://doi.org/10.1016/j.engstruct.2016.11.004

Marco Valente, Carlo A. Castiglioni, Alper Kanyilmaz, Welded fuses for dissipative beam-to-column connections of composite steel frames: Numerical analyses, Journal of Constructional Steel Research, Volume 128, 2017, Pages 498-511, ISSN 0143-974X, https://doi.org/10.1016/j.jcsr.2016.09.003

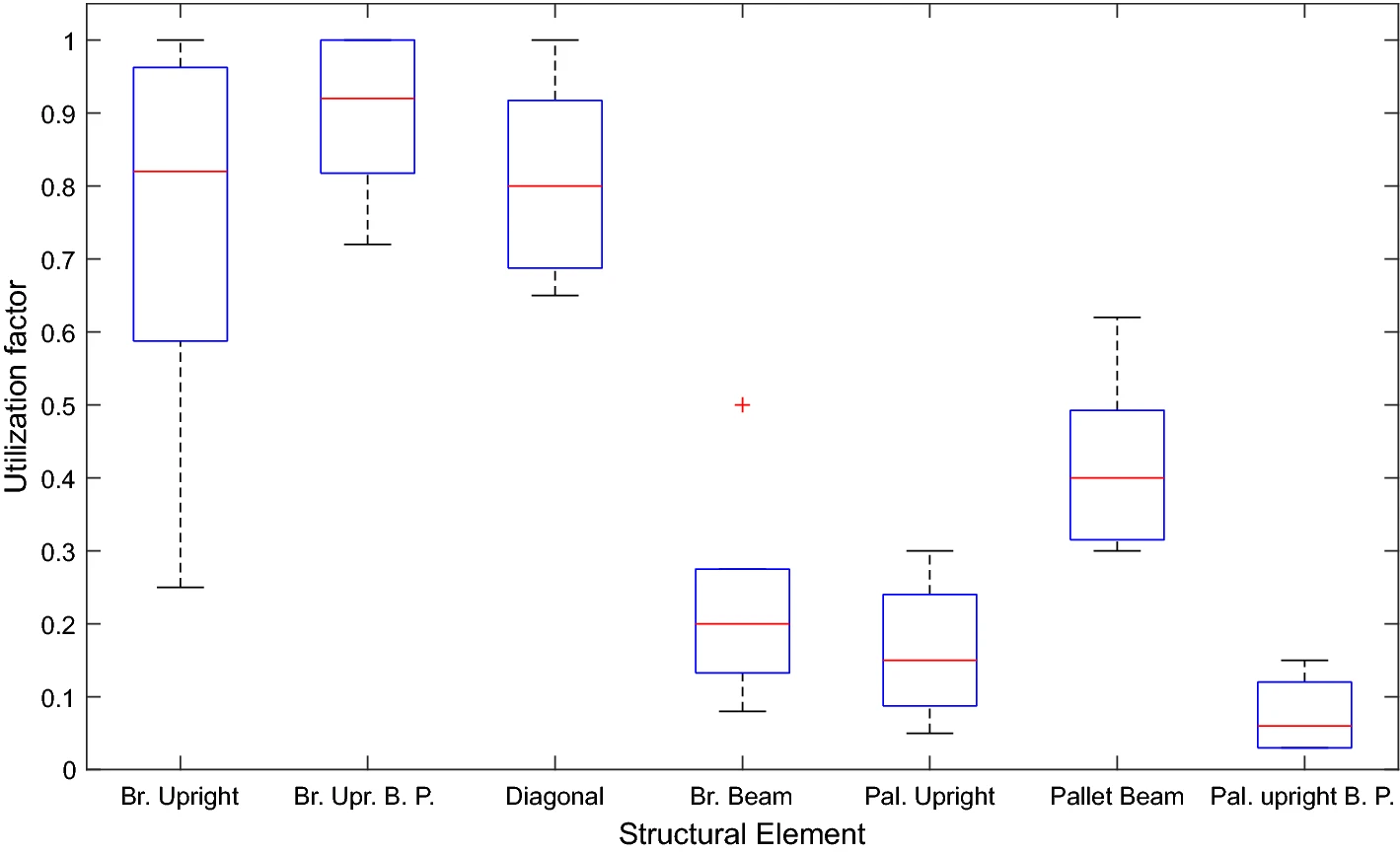

Racking systems (pallet racks and automated warehouses) in earthquake regions

Dr. Kanyilmaz has worked in advancing Automated Rack Supported Warehouses (ARSW), the cutting-edge in storage technology, offering significant reductions in cost, space, and energy compared to conventional warehouses. The goal is to introduce innovative strategies to enhance the safety, reliability, and cost-efficiency of ARSW. More details can be read in the following articles:

Alper Kanyilmaz, Giovanni Brambilla, Gian Paolo Chiarelli, Carlo Andrea Castiglioni, Assessment of the seismic behaviour of braced steel storage racking systems by means of full scale push over tests, Thin-Walled Structures, Volume 107, 2016, Pages 138-155, ISSN 0263-8231, https://doi.org/10.1016/j.tws.2016.06.004

Alper Kanyilmaz, Carlo Andrea Castiglioni, Giovanni Brambilla, Gian Paolo Chiarelli, Experimental assessment of the seismic behavior of unbraced steel storage pallet racks, Thin-Walled Structures, Volume 108, 2016, Pages 391-405, ISSN 0263-8231, https://doi.org/10.1016/j.tws.2016.09.001

Kondratenko, A., Kanyilmaz, A., Castiglioni, C.A. et al. Structural performance of automated multi-depth shuttle warehouses (AMSWs) under low-to-moderate seismic actions. Bull Earthquake Eng (2021). https://doi.org/10.1007/s10518-021-01193-y

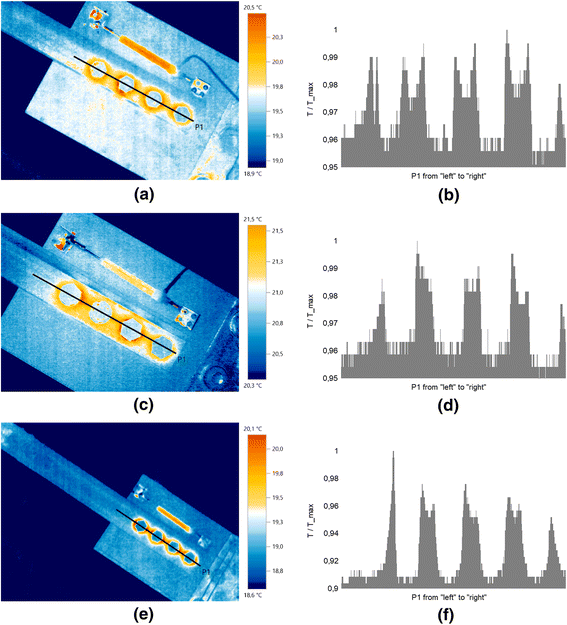

Carlo A. Castiglioni, Alberto Drei, Alper Kanyilmaz (2020) Continuous Monitoring of Service Conditions of a Steel Storage Racking System, Journal of Earthquake Engineering, 24:3, 485-505, DOI: 10.1080/13632469.2018.1453402

Carlo A. Castiglioni, Alberto Drei, Alper Kanyilmaz, Harris P. Mouzakis, Earthquake-Induced pallet sliding in industrial racking systems, Journal of Building Engineering, Volume 19, 2018, Pages 122-133, ISSN 2352-7102, https://doi.org/10.1016/j.jobe.2018.05.004

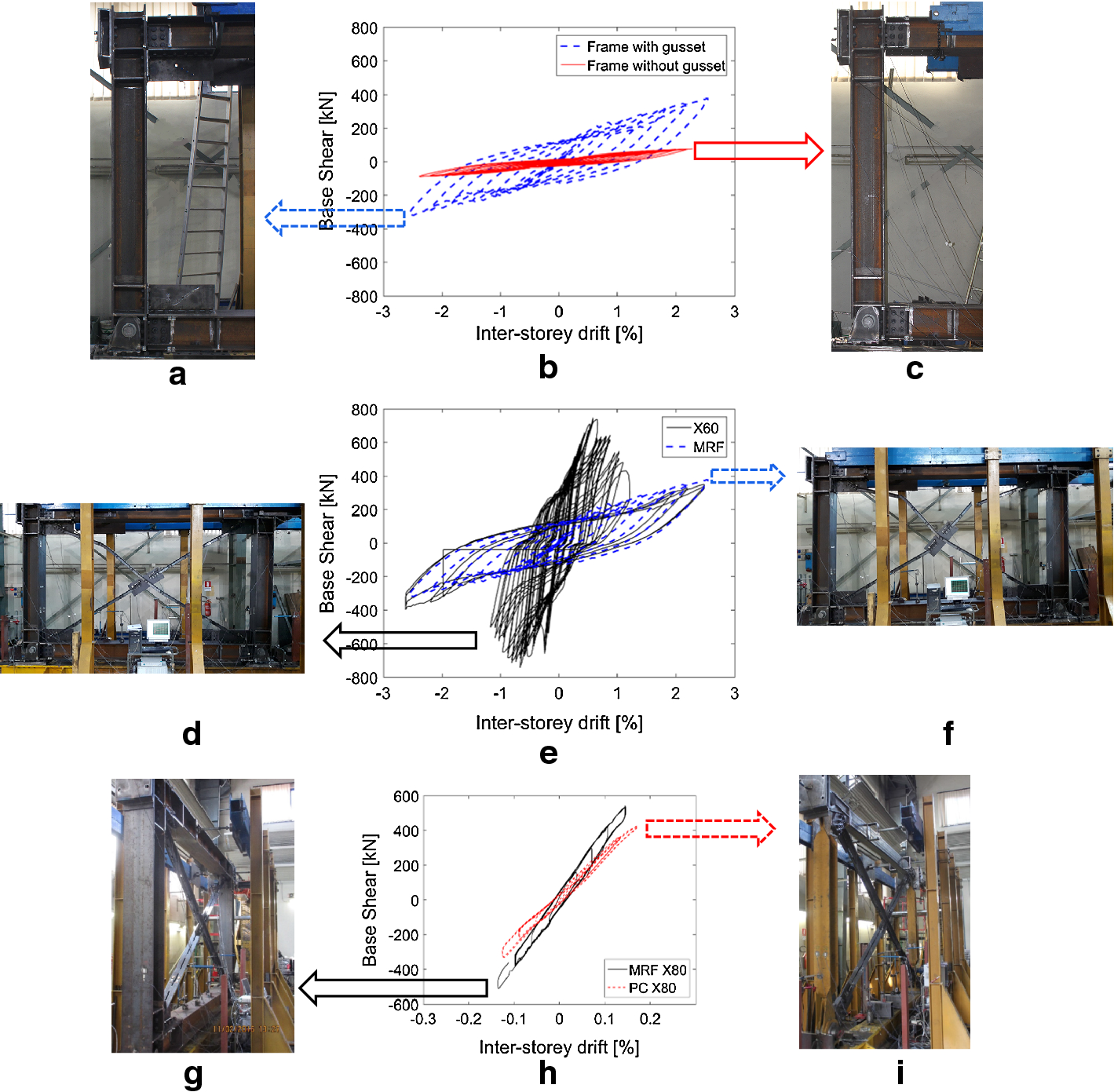

Seismic design of concentrically braced frames under low-to-moderate seismicity

Within MEAKADO research project, he proposed an adjusted design approach for the low-to-moderate seismicity design of Concentrically Braced Frame (CBF) structures. With the new approach, the aim was to satisfy both economy and safety criteria, based on the exploitation of the three features of CBFs, which had not been deeply examined before: “frame action provided by gusset plates”, “contribution of compression diagonal and its post-buckling strength and stiffness”, and “energy dissipation capacity of non-ductile bracing joint connections”.

His team investigated these aspects by means of incremental dynamic analysis of case studies, based on the numerical models calibrated on full-scale experimental tests published elsewhere by us.

Based on the results of full-scale experiments, his team quantified the ductility provided by the bolt hole ovalization and the slippage of preloaded bolts of standard bracing joints of concentrically braced frames that are not fulfilling the current over-strength design criteria.

More details can be read in these articles:

Kanyilmaz, A., Degée, H. & Castiglioni, C.A. An adjusted design approach for concentrically braced frames in low-to-moderate seismicity areas. Bull Earthquake Eng 16, 4159–4189 (2018). https://doi.org/10.1007/s10518-018-0402-0

Kanyilmaz, A., Role of compression diagonals in concentrically braced frames in moderate seismicity: A full scale experimental study, Journal of Constructional Steel Research, Volume 133, 2017, Pages 1-18, ISSN 0143-974X, https://doi.org/10.1016/j.jcsr.2017.01.023

Kanyilmaz, A. Secondary frame action in concentrically braced frames designed for moderate seismicity: a full scale experimental study. Bull Earthquake Eng 15, 2101–2127 (2017). https://doi.org/10.1007/s10518-016-0054-x

Kanyilmaz, A. Moderate ductility of the bracing joints with preloaded bolts. Bull Earthquake Eng 16, 503–527 (2018). https://doi.org/10.1007/s10518-017-0208-5

Related news

EU-RFCS DISSIPABLE final workshop

23 February 2022

EU-RFCS DISSIPABLE final workshop: Alper coordinated this 4 year research project composed of pilot-scale shaking table tests,

Automated warehouses, and massive racking structures

26 October 2021

The MSc thesis of Aleksei Kondratenko resulted in an elegant journal article (4 rounds of

… Continue reading Automated warehouses, and massive racking structures